First of all, non-degradable plastic tableware is an area that is explicitly prohibited by the state and currently needs to be combated. New materials such as PLA are also very popular, but many merchants have reported an increase in costs. Sugarcane pulp tableware equipment is not only cheap in raw materials, but also cheaper than new environmentally friendly materials such as PLA and PBAT. After that, the price will be lower and lower with the production volume and market scale. In the future, sugarcane pulp will become one of the main materials to replace plastics, so let’s learn about the future development prospects of sugarcane pulp tableware !

Sugarcane pulp tableware product positioning:

New material packaging can give new life to products, new material = new packaging = new product = corporate profit growth point.

Applicable scenarios of sugarcane pulp tableware :

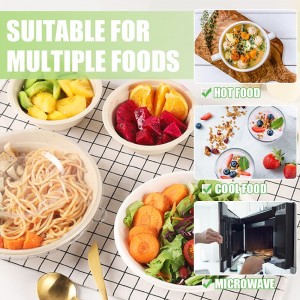

Supermarkets, restaurants, fresh fruit and vegetable distribution, takeaway, milk tea specialty stores, dine-in packaging, etc.

Benefits of Sugarcane Pulp Tableware:

Sugarcane pulp tableware is completely decomposed of raw materials, without any garbage residue and pollution. Comes from a natural eco-friendly container, the product adopts special technology, peeling, wrinkling and no leakage after use. Microwave 120, freezer -20, waterproof and oil-proof without applying pressure. With complete qualifications, advanced technology, and more than 100 patents, as a customized service provider for fully disassembled packaging consumables, it can provide environmentally friendly lunch boxes such as hot chain, cold chain, and hot cold chain, which are resistant to high temperatures and antifreeze.

The raw material of bagasse is a natural polymer compound, which can be degraded in the natural environment, sustainable supply, natural resources can be reused, and the cycle is endless. The raw material is natural, the production process is aseptic, and the disinfection test is strict. After the product is decomposed, it will not cause poison to the soil and air, and there will be no secondary pollution hazard. It can replace plastic products based on petroleum and paper products based on wood.

The comparison raw materials are waste paper pulp or straw fibers such as renewable wheat, reed, straw, bamboo, sugarcane, palm, etc., which come from a wide range of straw pulp, and sugarcane pulp is a natural and highly concentrated fiber raw material, and the product will be ready in 90 days in the natural state. It can be fully degraded, and it can also be composted by households and industries. On the contrary, non-degradable plastic tableware will produce a lot of harmful substances, pollute the environment and damage human health.

Environmentally friendly lunch boxes made of biodegradable materials, fully biodegradable materials, biodegradable granules, starch biodegradable materials, etc. can be completely and quickly degraded according to the design requirements in the soil and natural environment, non-toxic, pollution-free, and odor-free. Without destroying the soil structure, it really “comes from nature and exists in nature”. In recent years, with the introduction of “bans” and environmental protection promotion, people’s awareness of environmental protection has gradually increased, and the development prospects of sugarcane pulp tableware equipment are getting better and better.

GeoTegrity is the premier OEM manufacturer of sustainable high quality disposable food service and food packaging products. Since 1992, GeoTegrity has focused exclusively on manufacturing products using renewable raw materials.

We are also an integrated manufacturer who not only focuses on pulp molded tableware technology R&D and machine manufacturing, but also a professional OEM manufacturer in pulp molded tableware, now we are running 200 machines in house and exporting 250-300 containers per month to over 70 countries across 6 continents.

The above is the future development prospect of sugarcane pulp tableware. If you want to know more, please feel free to contact us!

Post time: Jul-10-2023