Food Container Making Machinery - LD-12-1350 Fully Automatic Free Trimming Free Punching Sugarcane Bagasse Pulp Molded Paper Plate Tableware Making Machine – Far East

Food Container Making Machinery - LD-12-1350 Fully Automatic Free Trimming Free Punching Sugarcane Bagasse Pulp Molded Paper Plate Tableware Making Machine – Far East Detail:

Main Feature

Fully automatic pulp molded tableware machine

Patented free punching free trimming technology, automatic collection, intelligent counting,15% lower production cost than semi-automatic equipment

The large work table(1350mm×1350mm) greatly increases the daily output of finished products.

Automatically and adjustable controlled by PLC.

Pneumatic and hydralic dual control,energy saving and high efficiency.

Accurate Product Weight Control

2-Stage Machine

Product Detail

The Main Forming Machine

Production Mold

Product Specifications

|

tomatic |

fully-automatic |

| Designed Capacity | 500-700kg/day |

| forming type | vacuum suction |

| Mould Material: | Aluminium Alloy:6061 |

| Raw material: | plant fiber pulp (any paper pulp) |

| Drying method | heating in mold(by eleatric or by oil ) |

| Auxiliary Equipment Power For Each Machine: | 51KW For Each Machine |

| Vacuum Requirement For Each Machine: | 11m3/min/set |

| Air Requirement For Each Machine: | 1.5m3/min/set |

| After-sales Service | Free spare parts, Video technical support, installation guidance, commssioning |

| Place of Origin | Xiamen city ,China |

| Finished Products: | Disposable ECO-friendly Tableware |

| Accepted Payment Type | L/C ,T/T |

| Accepted Payment Currency | CNY,USD |

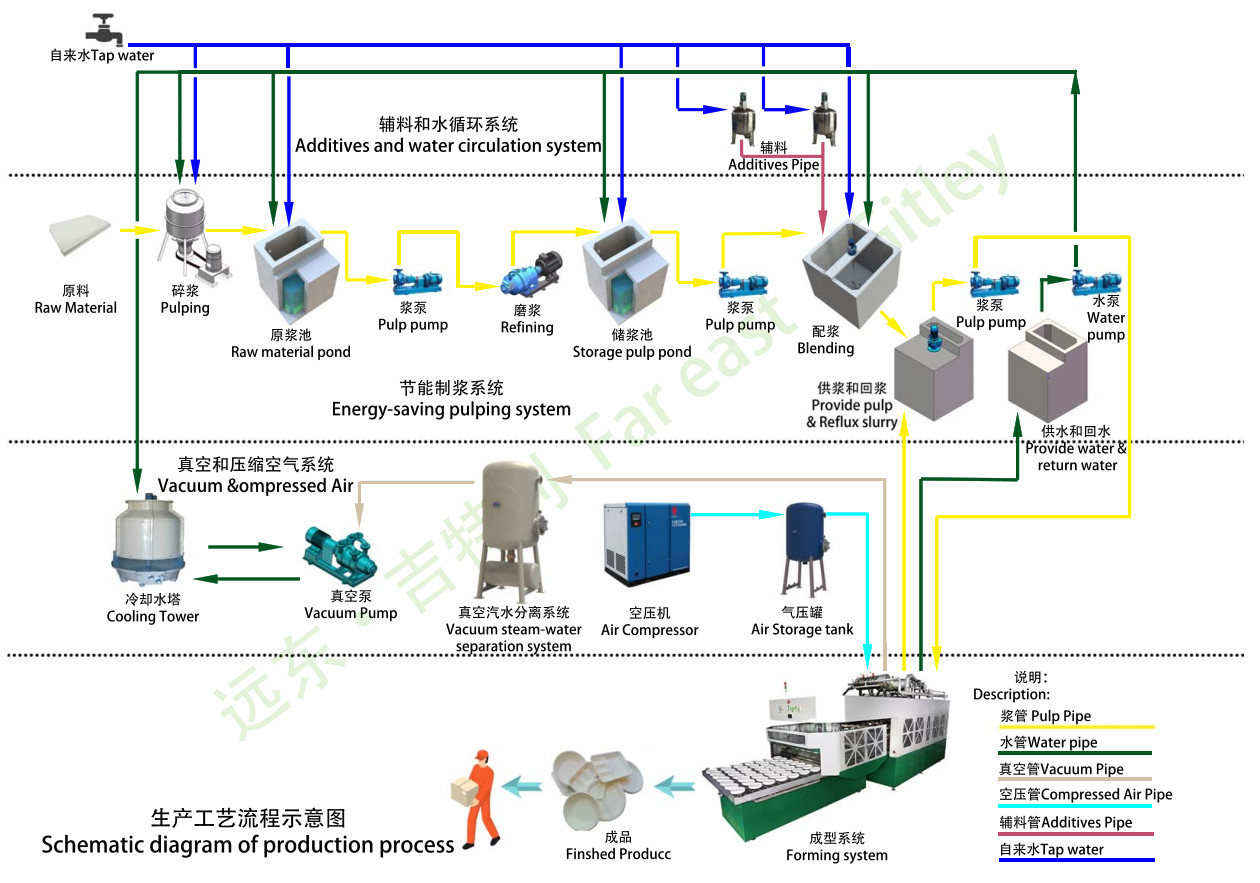

Engineering Drawing

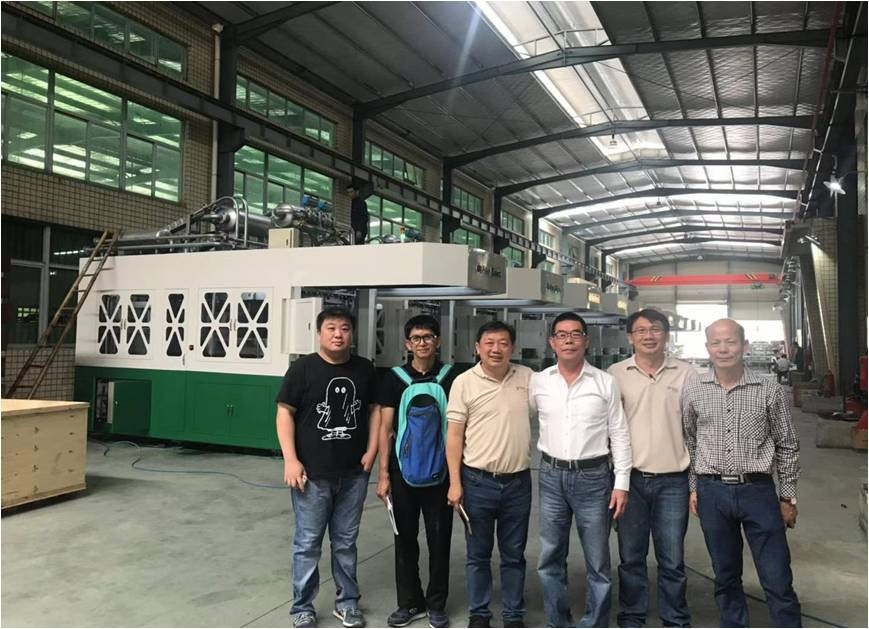

Cooperation Case

Application

The LD-12 series fully automatic pulp molded tableware machine is mainly applied for producing eco friendly disposable plates, bowls, trays, boxes, and other biodegradable food packaging items. Its large work table and fully automatic operation will bring you super high productivity.

Product detail pictures:

Related Product Guide:

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Food Container Making Machinery - LD-12-1350 Fully Automatic Free Trimming Free Punching Sugarcane Bagasse Pulp Molded Paper Plate Tableware Making Machine – Far East , The product will supply to all over the world, such as: Zambia, Senegal, Chile, We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.